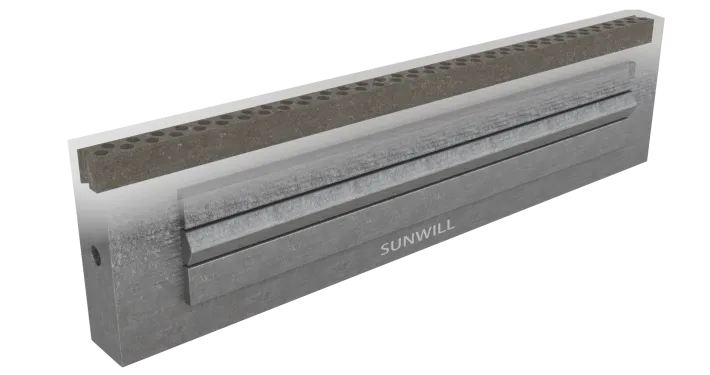

Blow Bars DETAILS

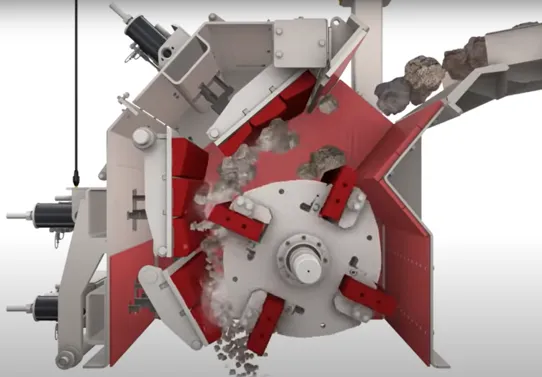

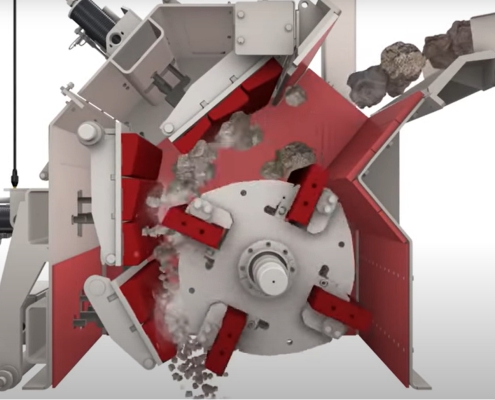

Blow bars are the most crucial wear parts in a HSI impact crusher that break big feed materials into smaller sizes. It is vertically mounted on the rotor and runs in a very high speed with the rotor. The objects feed from the open inlet of impactor are hit by the blow bars towards the impact plates which are mounted on the aprons and bounced back. The objects are shattered and size reduced during this process and discharged from the outlet of impactor.

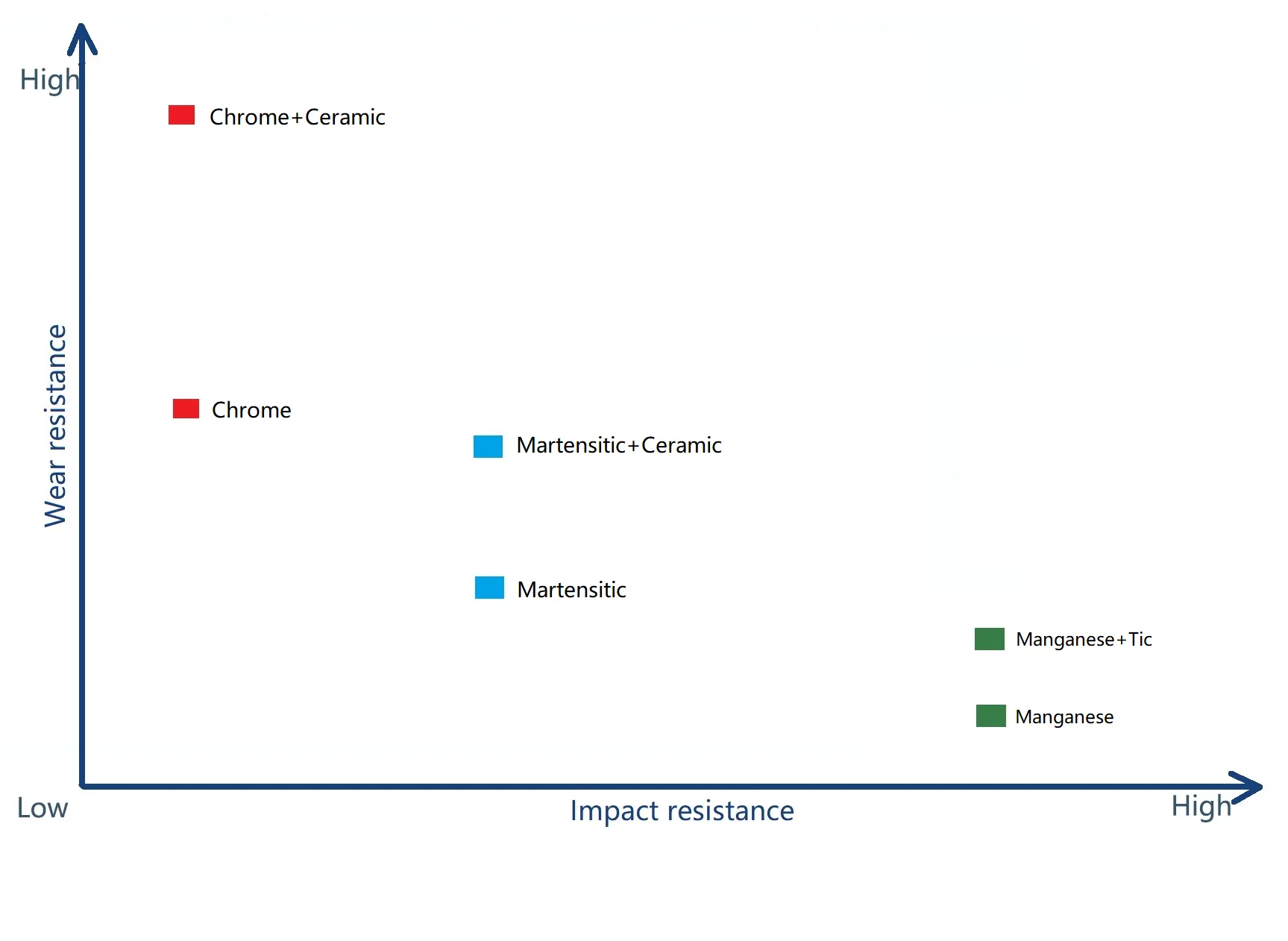

Due to this working principle, the blow bars withstand huge impact force and harsh abrasion during the crushing process. Hence, it is very important the select the right and reliable blow bars for impact crusher. Good blow bars will last as long as possible and don’t break.