Maximize Crusher Efficiency with Sunwill’s Gyratory Crusher Concave Liners

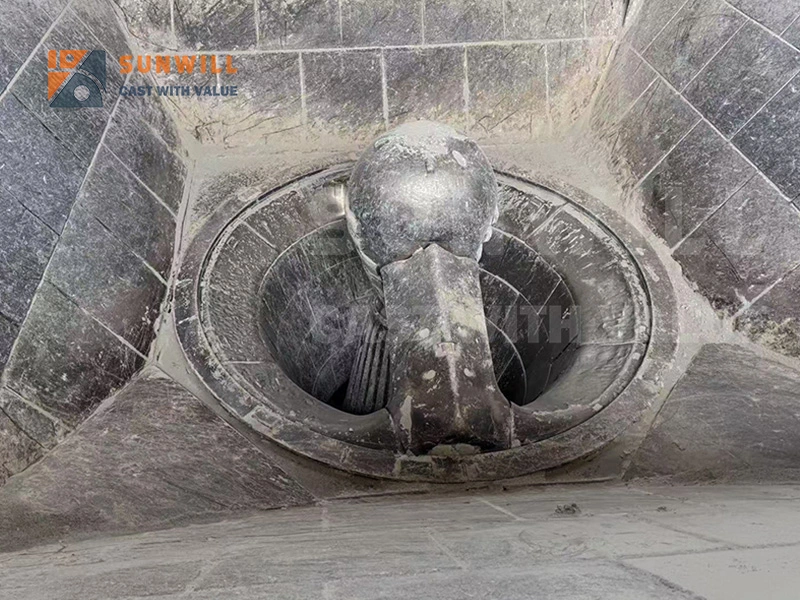

When it comes to ore and aggregate processing, the primary gyratory cone crusher plays a critical role in ensuring efficient and continuous operations. A major risk in crusher performance is unexpected shutdowns due to wear part failures, which can severely impact production timelines and operational costs. At Sunwill, we understand the importance of maintaining reliability in your crusher’s operation, which is why we provide high-quality gyratory crusher concave linersdesigned to ensure optimal performance, maximum uptime, and minimal maintenance.

Why Choose Sunwill’s Gyratory Crusher Concave Liners?

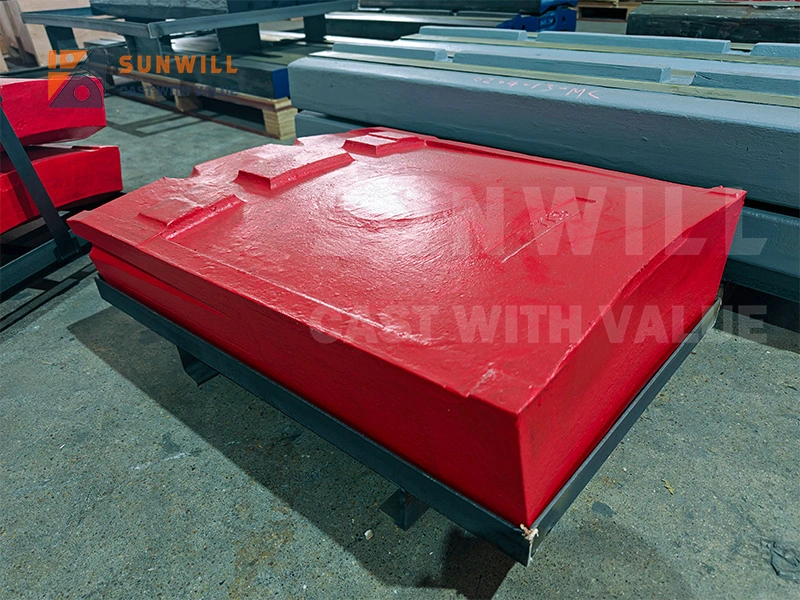

Sunwill’s gyratory crusher concave segmentsare engineered with precision to extend the lifespan of your equipment and enhance crusher efficiency. Made from high-chromeand alloy steelmaterials, our liners are designed to meet the toughest demands in ore and aggregate processing environments.

1. Superior Durability and Resistance

Our chrome steel concave linersoffer exceptional impact resistanceand abrasion resistance, ensuring that your crusher operates smoothly under the most demanding conditions. By using advanced alloy steel and high-chrome materials, we provide a reliable solution for maximizing uptime and minimizing maintenance costs.

2. Engineered for Maximum Efficiency

At Sunwill, we understand that every operation has unique requirements. Our gyratory crusher linersare specifically tailored to your needs, helping to maximize crusher efficiencyand throughput. With optimal wear performance, the liners reduce the frequency of part replacements and extend the overall lifespan of the crusher, resulting in increased productivity.

3. Designed for Easy Installation

Our concave linersare designed with ease of installation in mind, reducing downtime during equipment maintenance. This allows your operation to stay on track and minimize any disruptions.

4. Unmatched Quality Standards

Sunwill’s commitment to quality ensures that all our products meet the highest manufacturing standards. Our liners undergo strict quality control processes to ensure they exceed industry standards, providing you with confidence in every part we deliver.

The Importance of Choosing Quality Crusher Parts

Gyratory crushers are the backbone of most mining and aggregate operations. To ensure that these machines run at peak performance, using high-quality wear parts such as concave liners is essential. Poor-quality liners can lead to excessive wear, reduced crushing efficiency, and frequent equipment failure, ultimately increasing operational costs.

At Sunwill, we prioritize reliability. Our gyratory crusher concave segmentsare designed not only to withstand the wear and tear of heavy-duty crushing but also to enhance the overall performance and longevity of your machinery.

Contact Sunwill for Your Gyratory Crusher Needs

When it comes to gyratory crusher wear parts, Sunwill stands as a leader in the mechanical casting industry. With years of expertise and a commitment to excellence, we provide tailored solutions to meet your specific operational requirements. Choose Sunwill’s concave linersfor improved performance, reduced downtime, and increased productivity.

For more information or to get a quote on our gyratory crusher concave liners, contact Sunwill today.