MMC (Ceramic Inserts) and Bimetal

Sunwill is pround to be a foundry has MMC (Metal Matrix Composite) and also Bimetallic technology which enable us to manufacture longer life products to reduce downtime for customers in Quarry, Mining, Construction, Cement and Recycling industry.

MMC - Ceramic Inserted

A casting technology that embeds the ceramic grits into the casting at molten state. The ceramic is very hard with high hardness. By embeding ceramics on the wear suface of parts, it will largely enhance the ability of wear resistance of parts so as to increase service life of the parts in machines and reduce downtime of machines.

Solutions:

1, High chrome with ceramic inserts

2, Medium chrome with ceramic inserts

3, Martensitic steel with ceramic inserts

MMC technology is widely used to increase life time of blow bars and hammers for crushers and Grinding rollers for mills.

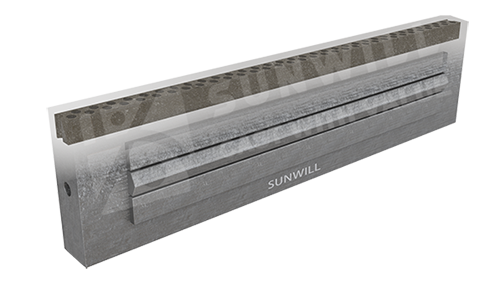

Bimetal

A wear technology that combines two or three different types of wear materials.

Soltuions:

1, Chrome casting backed with mild steel

2, Cement carbide and chrome casting backed with mild steel.

It combines the good wear performance of chrome casting or cemented carbides and the good impact resistance of mild steel. And also the mild steel backup is enable the plates to be weldable or attached with bolts.

Bimetal technology is used to make the wear plates and chocky bars for wear protection of crushers, chutes, excavator buckets, hoppers and other applications where good wear resistance and also good impact resistance are required.